Underfloor Heating

The future of heating

Acoustic flooring with underfloor heating (UFH) is increasingly specified for new builds and redevelopment projects. The combined system offers higher efficiencies compared with radiators, and frees up space that is at a premium in living spaces and apartments.

As more and more buildings convert to renewable heating sources such as air source heat pumps, the water feed temperature becomes lower. This change in heating systems makes underfloor heating the best option.

An integrated solution

We can design acoustic flooring with underfloor heating to suit individual design and programme requirements. Ask about UFH systems to suit your project.

Our team work closely with Mechanical & Electrical contractors at all interfaces to deliver a smooth installation with optimum results.

We fully commission the UFH system by connecting it, flushing it completely and dosing it with Biocides and Inhibitors for long lasting protection that maintains effective operation.

EdB System

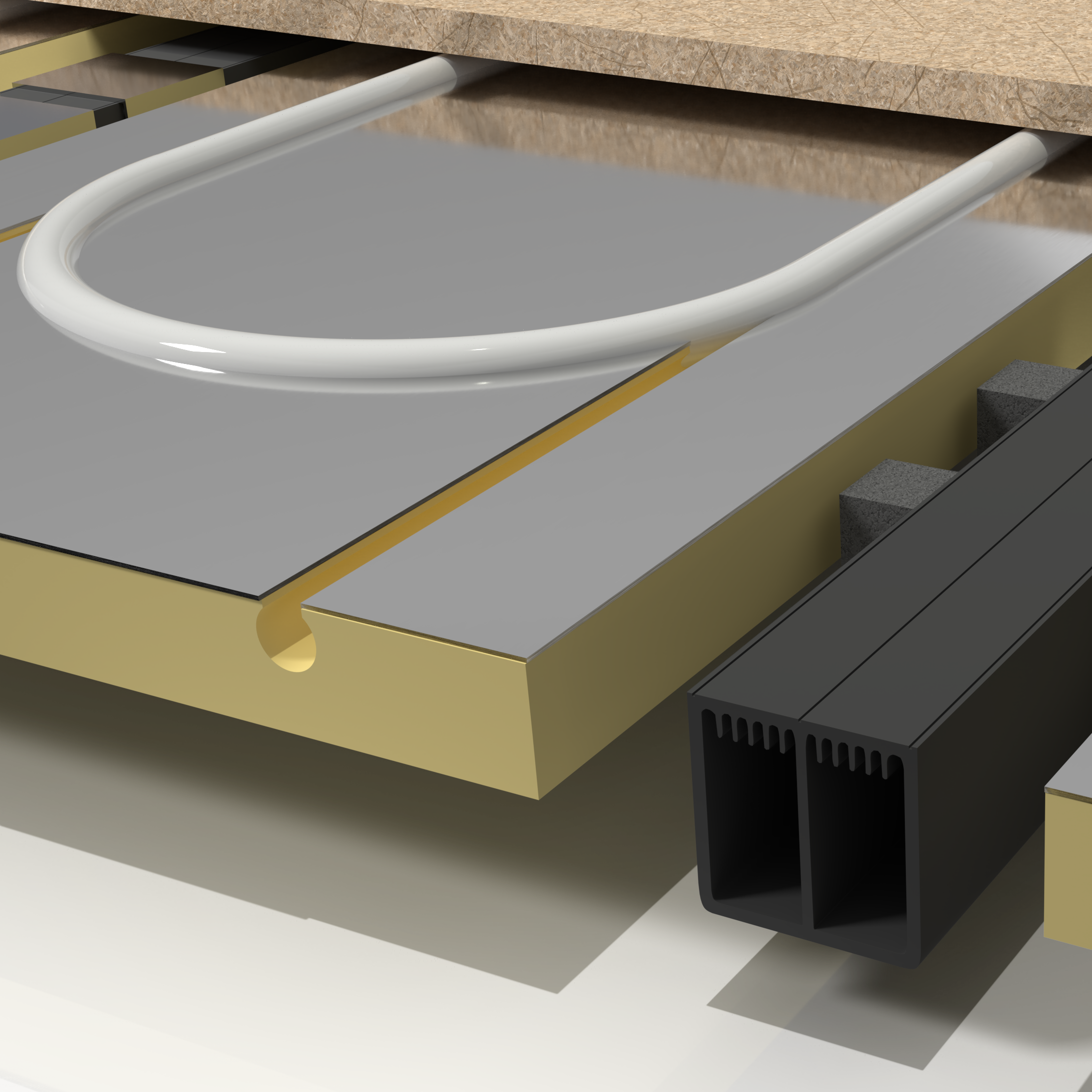

The EdB system works by holding the pipework in rigid, foil-faced, routed-out sheets of insulation which are held in place with galvanised steel brackets. When the overlay board is secured, the pipes stay in direct contact, creating maximum thermal efficiency.

Mounting the steel brackets on the battens means we can level the insulation with the overlay board and not the slab, eliminating air gaps. The rigid insulation then maintains a consistent connection with the overlay board and the pipe.

Typical components include:

- Actuators

- Wiring centres

- Programmable thermostats

- Manifolds

- Pipework

- Routed out insulation and brackets holding the pipework

Aluminium Spreader Plates

Mineral wool is placed beneath the aluminium plates and between the battens to increase thermal performance.

The aluminium plates are flexible, and it’s important that they don’t sag, as this creates an air gap which would reduce the thermal efficiency of the system. Our fitters are trained in the optimal installation of the system to deliver to specifications.

Typical components include:

- Actuators

- Wiring centres

- Programmable thermostats

- Manifolds

- Pipework

- Single piece aluminium plates

Case Studies.

View all Case Studies